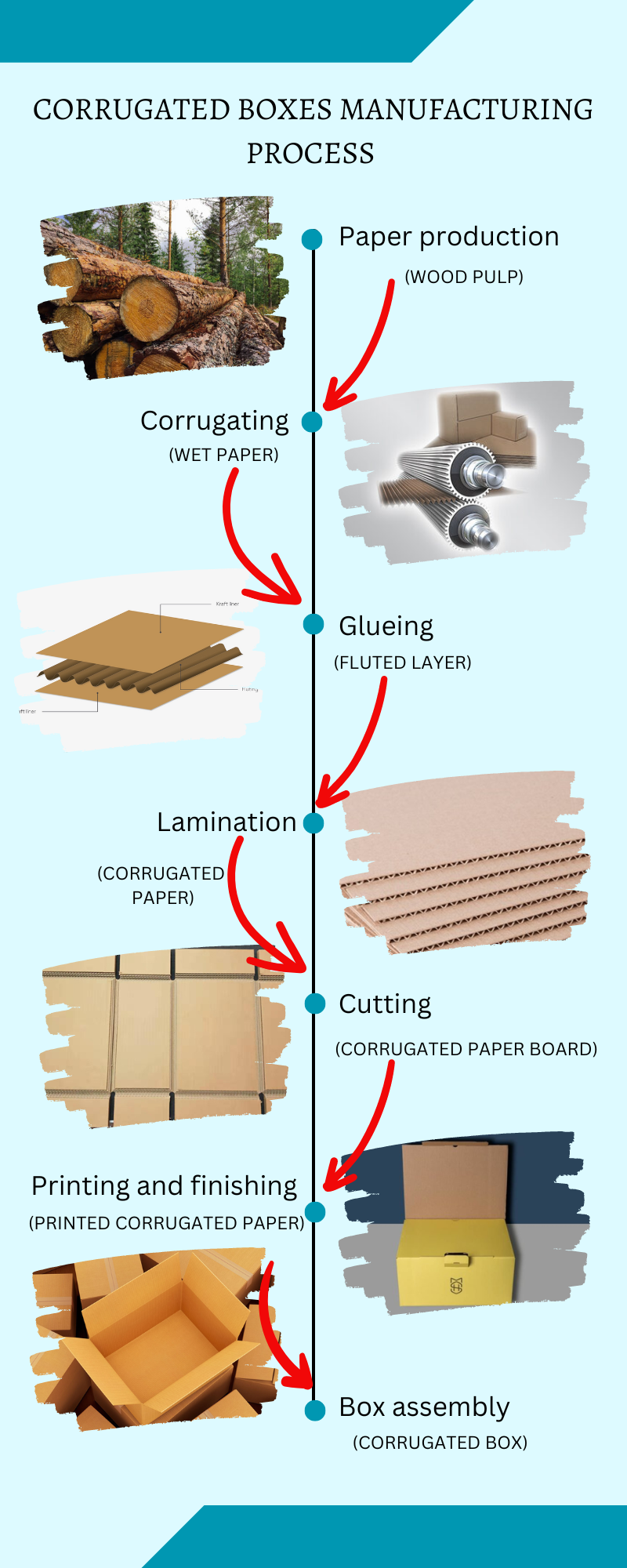

Most people use corrugated boxes, but does anyone know how corrugated boxes are made? Corrugated boxes are manufactured using three materials: paper, steam, and adhesive. Following are the steps involved in manufacturing corrugated boxes:

Paper is one of the basic materials used to make corrugated boxes. Paperboard material is made from wood pulp. These wood pulps are blended with water to create slurry pulp, which is passed through a wire screen when the water is dried, leaving a continuous sheet of wet paper behind.

The wet paper is passing through the corrugating roll. These rolls have a wave-like design and press the wet paper between them to form the corrugated board’s distinctive fluted layer.

After corrugating, starch-based adhesive is applied to the fluted layer of the board to connect it to the inner and outer layers.

In this step, the fluted layer is sandwiched between the inner and outer layers (the linear layer). Both the inner and outer layers are made from paperboard.

After lamination, the corrugated board is cut into specific-size sheets.

In this process, you can add specific elements such as logos, graphics, and so on.

The cut and printed sheets are folded and glued at certain points to make the final corrugated boxes.

We are the leading corrugated cardboard roll manufacturers in Chennai. We cater to provide best quality corrugated box and roll for range of industries.